Simple and economical friction type torque limiter

Suitable for working in dusty conditions, no need for speed adjustment between gearbox and output equipment

No noise and vibration when overloaded

Rotation two-way protection

Non-asbestos friction disc

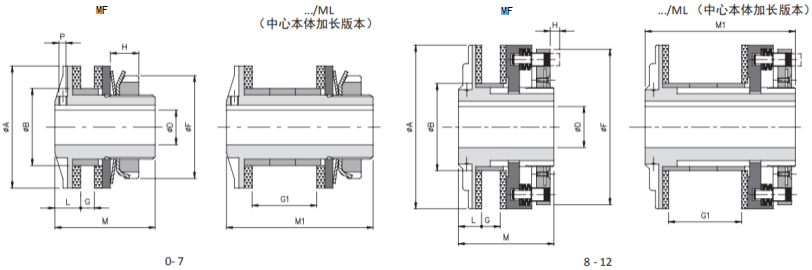

It is adjusted by the locking ring, the torque setting is simple and accurate

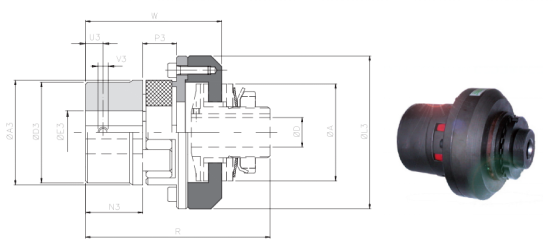

Innovative dimensional calibration system, which can calibrate the equipment instantaneously

On demand

Equipped with a complete transmission gear, all turned and assembled (sprocket, pulley, gear pair)

Various friction plates suitable for specific purposes

Multiple connection methods such as keyway, spline and expansion sleeve can be provided

The surface layer is treated with anti-corrosion to meet special requirements

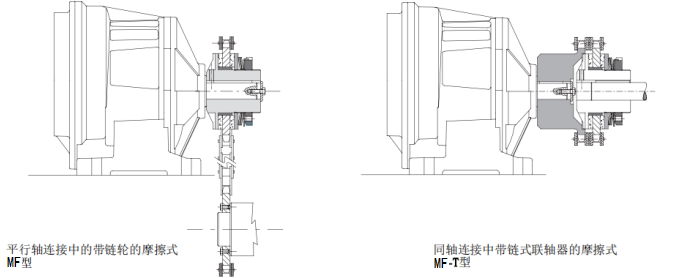

The sprocket, pulley or other transmission components in the friction torque limiter are installed between the two sliding plates. When the torque is reached, it can ensure continuous transmission without damaging the components. The characteristics of the device are: simple structure, low price, suitable for use in environments where torque accuracy is not very high.

Main application

Forming machinery

Conveying machinery

Fan

Agricultural machinery, woodworking machinery

Advantages and features

Protect the motor gearbox in an accidental collision

In case of overload, the conveyor line can be stopped in time

Protect the motor and blade when the blade is stuck

Protect the gearbox in the case of short-term blockage of the product