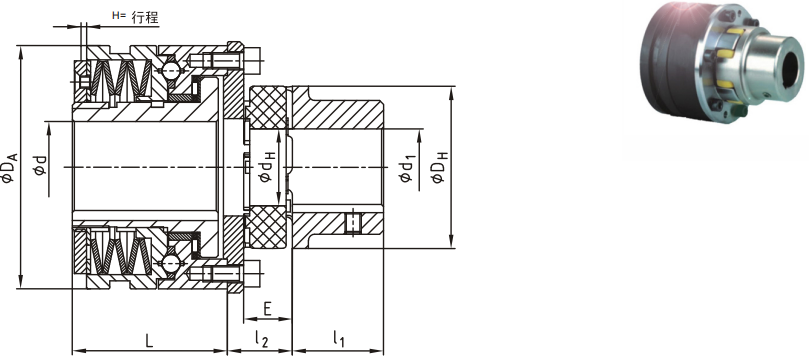

Accurate torque setting is achieved by adjusting the radial balance nut

"H size" innovative calibration system, which can perform instantaneous calibration of equipment

Single-point reset or 360°equal interval re-engagement

Transmission disconnection can be realized by electromechanical switch/proximity switch

Compared with electronic systems, the device can directly intervene, and the response capability is improved.

No maintenance, long service life, high stability

Suitable for working in humid and oily environment

On request

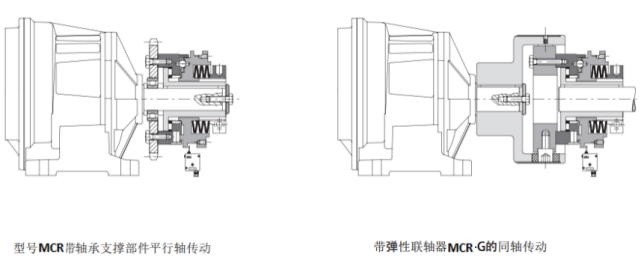

Equipped with a complete set of transmission gears, all made by turning, and installation is complete (sprockets, pulleys, gear pairs)

For low intervention torques, coil springs can be used

Connected by opening and keyway or expansion sleeve

Customized version, which can be re-engaged at 15°, 30°, 45°, 60°, 90° and other angles

The safety coupling realizes motion transmission through rollers, allows complete separation when the calibrated torque is reached, and quickly stops transmission through a micro mechanical switch. It is suitable for working under torque conditions, with high stability and compact structure.

Main application

Packaging and packaging machinery

Labeling machinery

Bottling machinery

Conveyor

Advantages and features

Protect the gearbox when external matter causes jams

Protect the packaging from breakage and deformation

When accumulation occurs, protect the product lifting components

Protect the drive and driven device in the event of an overload