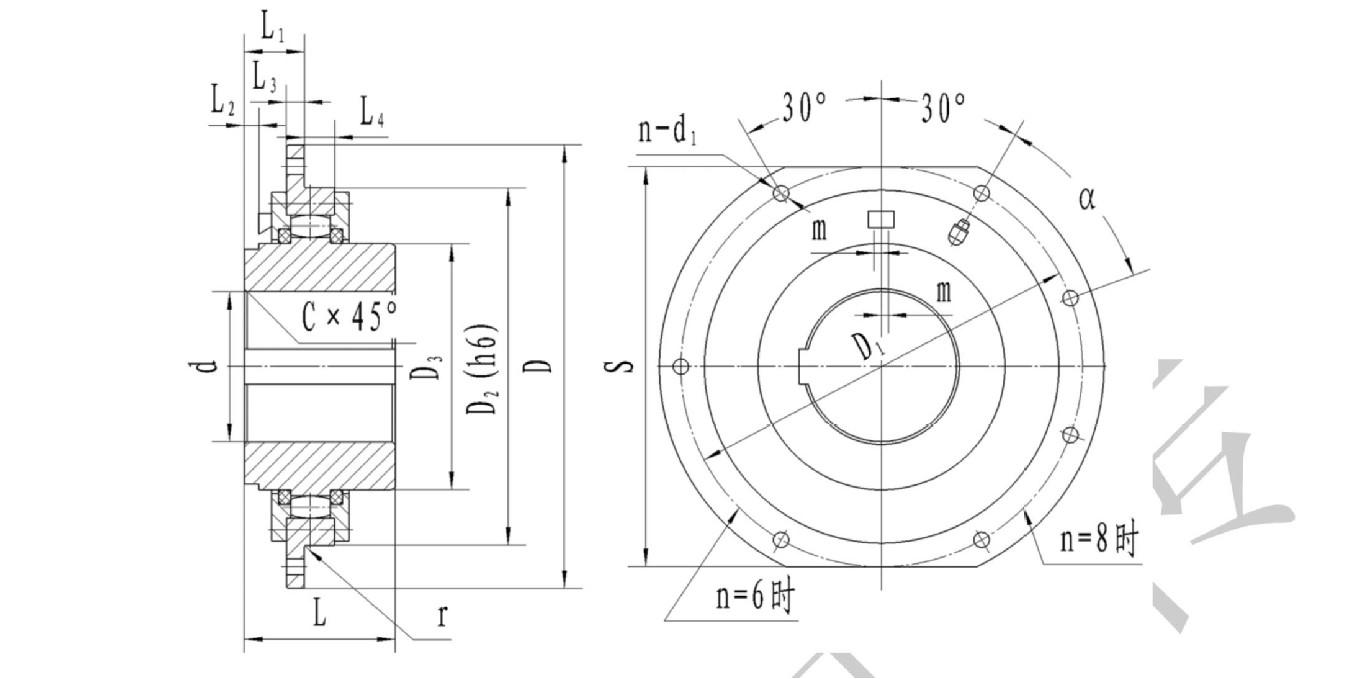

标准编号:JB/T 7009-1999

联轴器类型:Spherical roller coupling

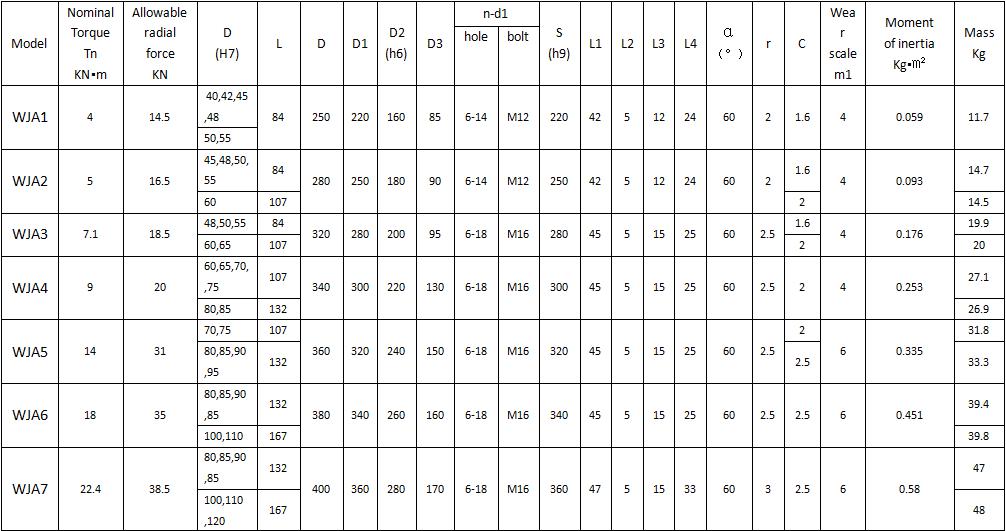

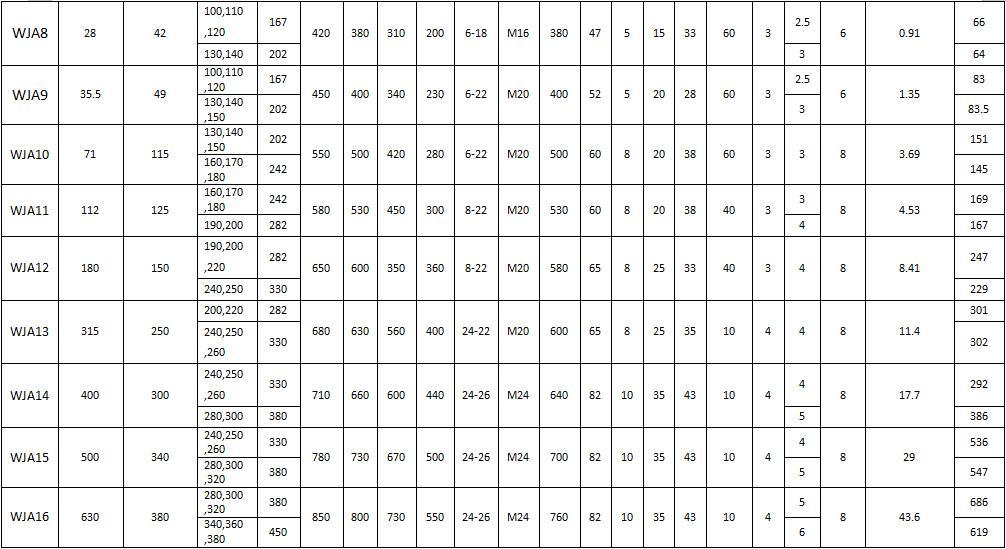

公称转矩:4~630(N.m)

轴孔:40~380

外形尺寸:250~850

孔径:40~380

重量:11.7~686(kg)

长度:84~450

外径:250~850

是否提供加工定制:Yes