◆Structure characteristics:

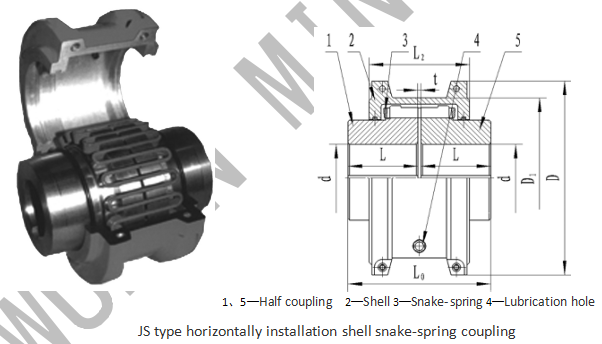

It belongs to an advanced structure of metal elastic variable stiffness coupling. It relies on a serpentine spring to be embedded in the tooth groove of two coupling halves to transmit torque. It is mainly composed of two coupling halves, two casing halves, and two seals. Composed of coils and serpentine springs.

◆Working principle and service life

The coupling is axially embedded in the tooth grooves of the two coupling halves with a serpentine spring plate to realize the coupling of the driving shaft and the driven shaft. During operation, the driving force is driven by the circumferential force of the tooth at the driving end facing the reed to transmit torque, so to a large extent the resonance phenomenon is avoided, and the elastic deformation of the reed when transmitting torque , So that the mechanical system can obtain better vibration reduction effect, and its average vibration reduction rate is more than 36%. The serpentine spring leaf is made of high-quality spring steel. After strict processing and treatment, it has good mechanical properties, so that the service life of the coupling is greatly increased compared with the non-metallic elastic element coupling.

◆High transmission efficiency and safe starting

The transmission efficiency can reach 99.47%, its short-term overload capacity is twice the rated torque, and the operation is safe and reliable.

◆Simple structure and convenient disassembly

Fewer parts, less volume and lighter weight, the serpentine spring is generally composed of 2 pieces or 3 pieces and more than 3 pieces, making disassembly and assembly and maintenance more convenient than other couplings.